Heat exchangers

Our heat exchangers are custom made depending on the customer's needs and the type of application.

This customization also ensures that our heat exchangers are the ideal solution for Retrofit.

Possible applications:

- Heating

- Cooling (ice water or DX)

- Condensation

- Evaporation

- Steam production

- Heat recovery.

Frames

The frames are made of galvanized steel plate, stainless steel 304/316, Cu, Al off brass, according to a design that ensures that the fins and bends are well protected. The tube holes in the tube plate are provided with collars of the same material as the fins, so that the tubes can move freely and fractures due to thermal expansion are prevented.

Tubes

For the pipes choice of:

We use tubes made of Cu, CuSn, CuNi or stainless steel (304/316) with different diameters and internal finishes.

This is to construct the most suitable heat exchangers for the user's requirements. Tin-plated tubes have anti-corrosion properties, while slotted tubes provide much better energy exchange A hairpin bender is used to make tubes for heat exchangers with fin lengths up to 4,000 mm, and a pipe puller for longer lengths. Great attention is paid to the mechanical expansion of the tubes, which must maintain perfect contact with the fins for optimal heat exchange.

Fins

The frames are made of galvanized steel plate, stainless steel 304/316, Cu, Al off brass, according to a design that ensures that the fins and bends are well protected. The tube holes in the tube plate are provided with collars of the same material as the fins, so that the tubes can move freely and fractures due to thermal expansion are prevented.

Protective Coatings

BLYGOLD

Blygold is a polyurethane coating with aluminum pigments. It gives long-term protection to heat exchangers without reducing efficiency or causing pressure loss, and can be applied during manufacturing or on site. A thin layer of Blygold provides good heat exchange and a high level of chemical protection. When applied by certified technicians working to Blygold's specifications, PoluAl XT is highly effective in preventing damage to air conditioning systems and reducing excessive energy consumption. Corrosion resistance (ASTM B117): 4,000 hours.

Blygold is a polyurethane coating with aluminum pigments. It gives long-term protection to heat exchangers without reducing efficiency or causing pressure loss, and can be applied during manufacturing or on site. A thin layer of Blygold provides good heat exchange and a high level of chemical protection. When applied by certified technicians working to Blygold's specifications, PoluAl XT is highly effective in preventing damage to air conditioning systems and reducing excessive energy consumption. Corrosion resistance (ASTM B117): 4,000 hours.

HERESITE

This is an anti-corrosion coating based on thermosetting phenolic resins for special applications where complete coverage of the heat exchanger is required. It provides high corrosion resistance in maritime and saline environments and is effective against a wide variety of corrosive vapors, chemicals and condensates. HERESITE coating is widely used in the HVAC-R industry because it significantly extends the life of heat exchangers, coils and other air and smoke treatment equipment manufactured from light metals. Resistance to corrosion

(ASTM B117): 6,000 hours.

(ASTM B117): 6,000 hours.

THERMOGUARD

Thermoguard has developed Finguard Silver SB for the protection of heat exchangers. This polyurethane coating with aluminum pigments protects against saline environments, chemical agents and UV radiation. Finguard Silver SB is applied as a spray by certified operators, both in the plant and on site. Corrosion resistance (ASTM B117): 3,000 hours. Color: silver

ELECTROFIN

This is an ideal anti-corrosion treatment applied by immersive cathodic electrodeposition. It can be customized with specific chemical formulations to meet the technical characteristics of each heat exchanger. Electrofin E-Co is suitable for marine environments, the consistency and uniformity of its protective film providing protection against a wide variety of corrosive chemical atmospheres. Guaranteed for 5 years, corrosion resistance (ASTM B117): 6,000 hours.

This is an ideal anti-corrosion treatment applied by immersive cathodic electrodeposition. It can be customized with specific chemical formulations to meet the technical characteristics of each heat exchanger. Electrofin E-Co is suitable for marine environments, the consistency and uniformity of its protective film providing protection against a wide variety of corrosive chemical atmospheres. Guaranteed for 5 years, corrosion resistance (ASTM B117): 6,000 hours.

TIN-COATING

Tinning is an electrolytic dipping treatment used to protect metals such as copper, iron, aluminum and their alloys. Compact tinned coatings are widely used for protection against atmospheric agents, water, solutions and many other substances, including foodstuffs. In addition to high corrosion resistance, tinning provides visual appeal and very high electrical conductivity.

CATAPHORESIS

This is an electrodeposition coating process recommended for applying a primer to the surface of elements of iron, steel and other alloys. It provides excellent resistance to atmospheric corrosion and other forms of deterioration, and improves the adhesion of powder coatings. This type of coating has poor resistance to exposure to UV radiation, and is therefore not suitable for use in direct sunlight.

SPECIAL COLORS

ANTIMICROBIAL

The transparent antimicrobial coating helps maintain heat exchanger life and hygienic conditions with a 99.99% reduction in bacteria levels in air-conditioned environments such as operating rooms, clean rooms, laboratories and shopping malls.

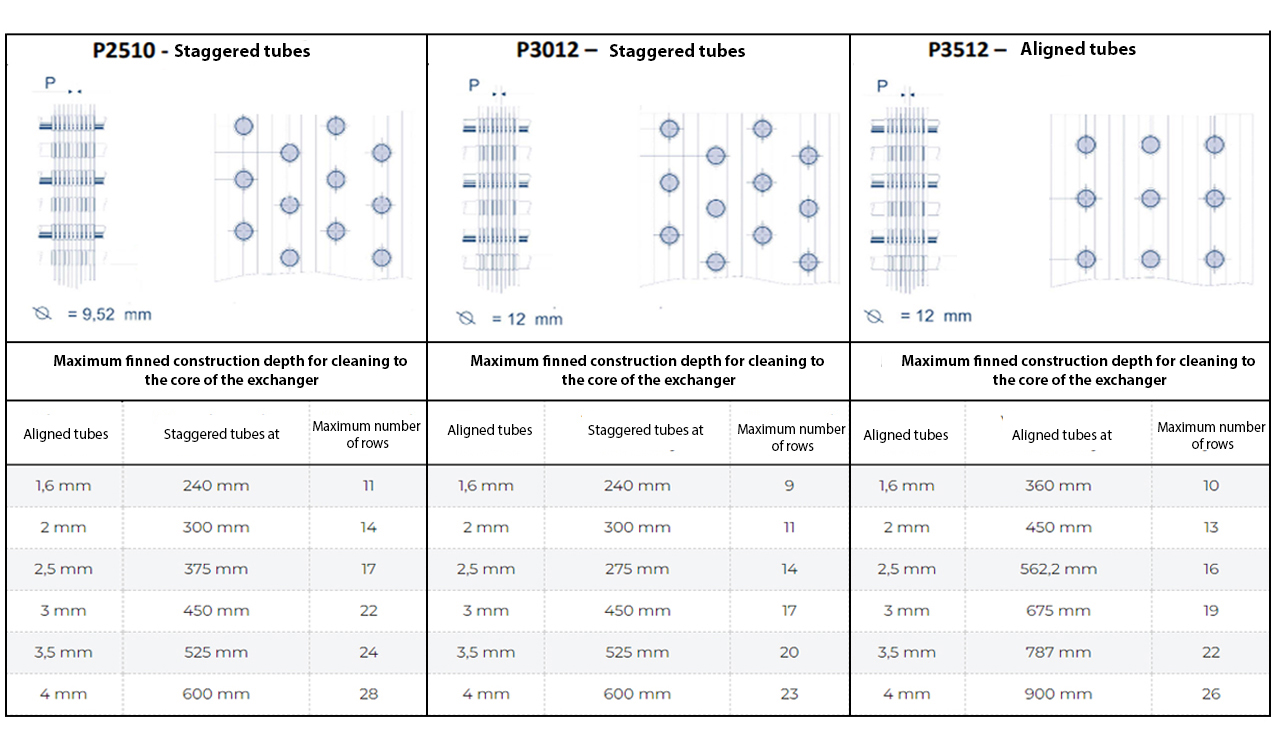

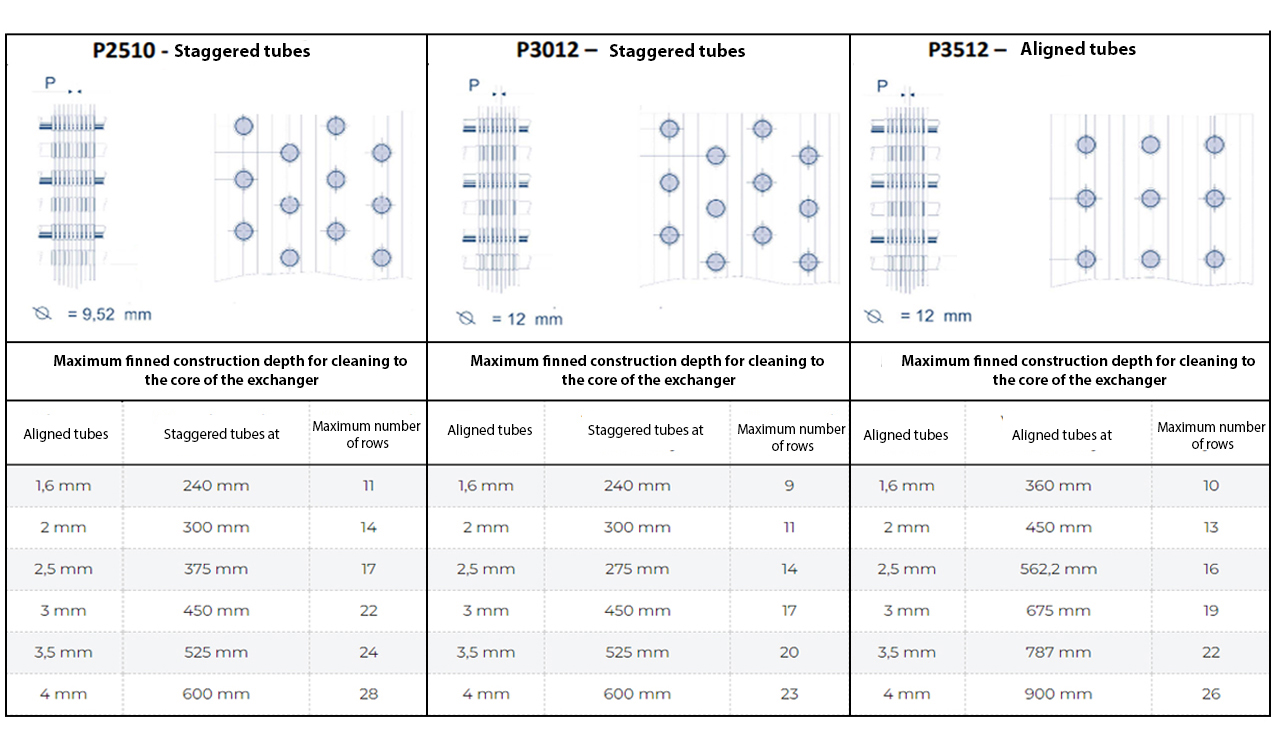

Possible heat exchanger configurations

Choice of different tube diameters and spacing of tubes and fins.

Some examples:

Some examples: